FOX (Food in a box) aims to rethink the way we process food. The project values sustainability and health while focussing on meeting consumer expectations towards local, qualitative foods. To achieve this, FOX uses mild processing technologies, such as High Pressure Processing. The use and advantages of this technology are explained in this article. In the FOX project, Polish and Dutch scientists (Warsaw University of Natural Sciences, Wageningen University & Research) are working with this technology in Food Circuits 2 and 4.

High pressure processing (HPP) can inactivate microorganisms and enzymes in food and thus render them harmless. This prolongs the shelf life of food. In addition, high pressure treatment can change a food so that it can be frozen or defrosted more gently.

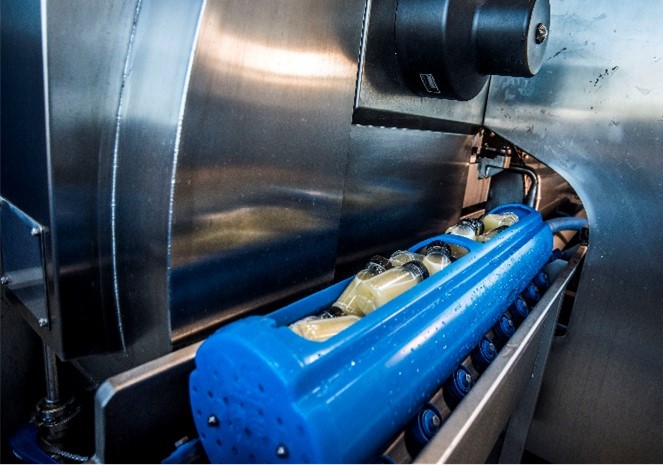

With HPP treatment, food is exposed to very high pressures for a few minutes in a chamber that is filled with water. The high-pressure process is also called the “non-thermal process”. This means that the food does not have to be heated significantly during processing, but is still preserved.

50l high pressure unit (Image: DIL)

What is the science behind HPP?

The physical principle of high-pressure treatment is based on two laws1:

- The “isostatic principle”, which states that pressure expands uniformly and directly on a biomass to be treated. With thermal treatment, the heat must be conducted from the outside to the inside, which leads to an uneven impact of the thermal energy, depending on the size and shape of the good to be processed. The advantage of HPP is that there is no efficiency gradient from the outside to the inside and the food can be processed regardless of its structure.

- On the other hand, the physical law of the “principle of least constraint”. According to this, under high pressure, reactions associated with a decrease in volume take place preferentially, whereas reactions associated with an increase in volume tend to be suppressed. Here, large molecules (i.e. proteins and enzymes) are more likely to be altered in contrast to small molecules (i.e. vitamins, colourings and flavourings). In addition, the pressure treatment leads to a physical denaturation of vegetative cells and essential enzymes, resulting in an additional decontamination/shelf life extension.

How can HPP be used in the food industry?

High pressure pasteurisation (HPP) can currently be used to reliably preserve liquid to pasty fruit and vegetable products while maintaining a high level of quality. The main advantage is an improved preservation of the general sensory properties as well as the content of temperature-stable substances such as vitamins (especially vitamins A, E and C) and secondary plant constituents (especially phenolic substances such as anthocyanins, etc.). Through the non-thermal treatment, the small molecules (i.e. vitamins) are largely protected, while those of oxidising enzymes (proteins leading to changes in colour of the product) are inhibited. The latter also occurs with enzymes that destroy the plant cell tissue or its texture in the course of storage. HPP treatment in fruit/vegetable products (fruit preparations, fruit juices) is approved for pasteurisation.

Reference:

- Berghofer E., Schönlechner R. and Schmidt J. 2015. New processes and techniques in food production and food supply – Importance for consumers.