Food Circle 2: Low temperature drying

The aim

Food Circle 2 aims to

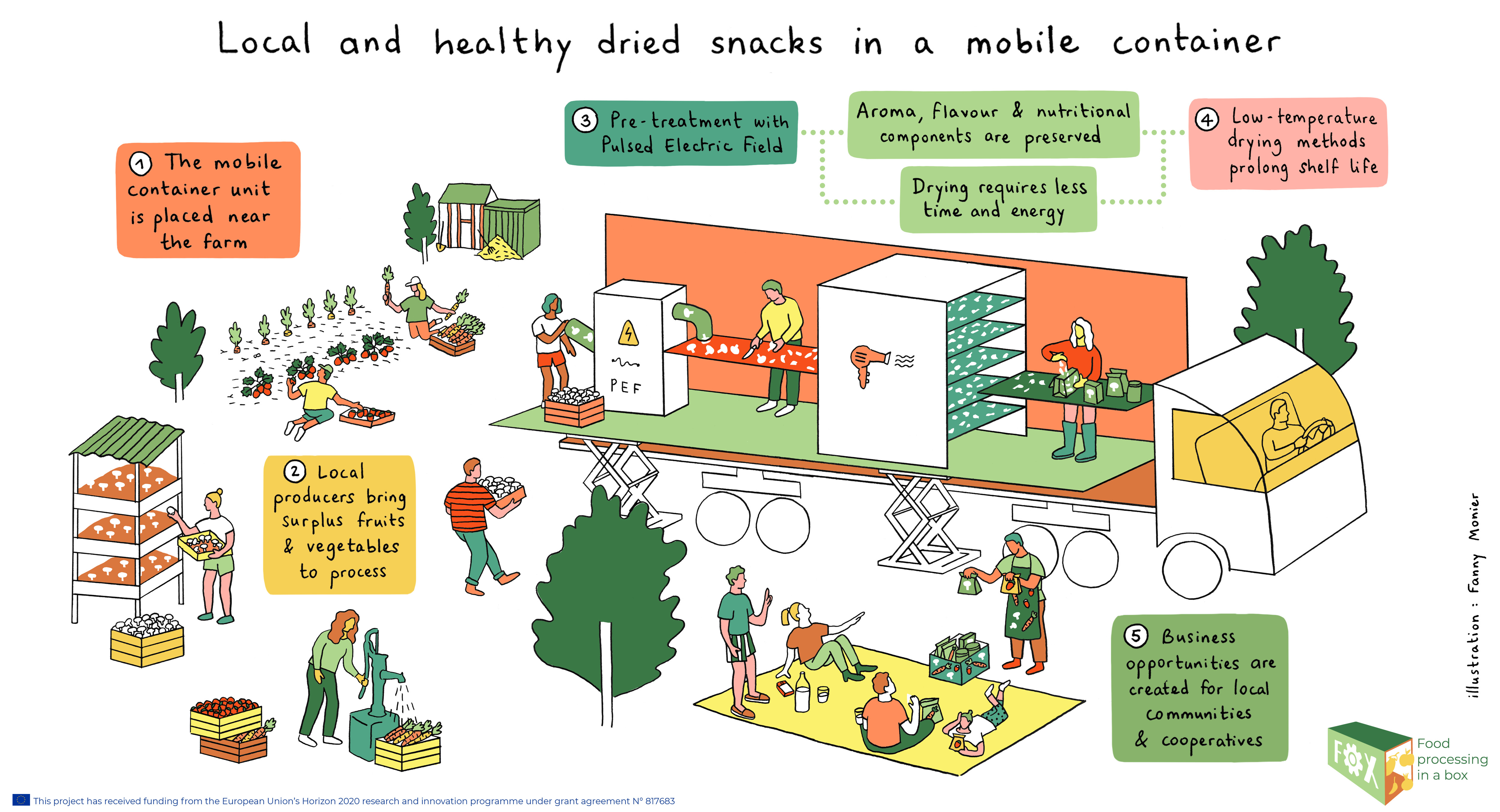

- Add value to fruit and vegetable products

- Open new business opportunities for farmers

- Manage the surplus of crops/produces

Soft fruits, vegetables and mushrooms often cannot be served as ready to eat food. Drying of fruits and vegetables can be a valuable alternative for farmers when the economic situation is not favourable for direct sale of the fresh products.

Plant-based materials can be dried in different ways:

- Conventional: convection oven

- Unconventional: dehumidified air, microwave, infrared and vacuum drying

However, non-thermal, pre-treatment methods (PEF, US, and HPP) used before the main drying process can result in different quality outcomes of plant-based material.

Find out more about drying technologies.

Non-thermal pre-treatment methods

The effect of non-thermal pre-treatment methods PEF, US and HPP on conventional and unconventional drying techniques will be analysed.

The mild drying technology will be downscaled for use in mobile container unit on location. The downscaling makes it easier to perform changeovers while drying different foods.

Find out more about PEF and HPP.

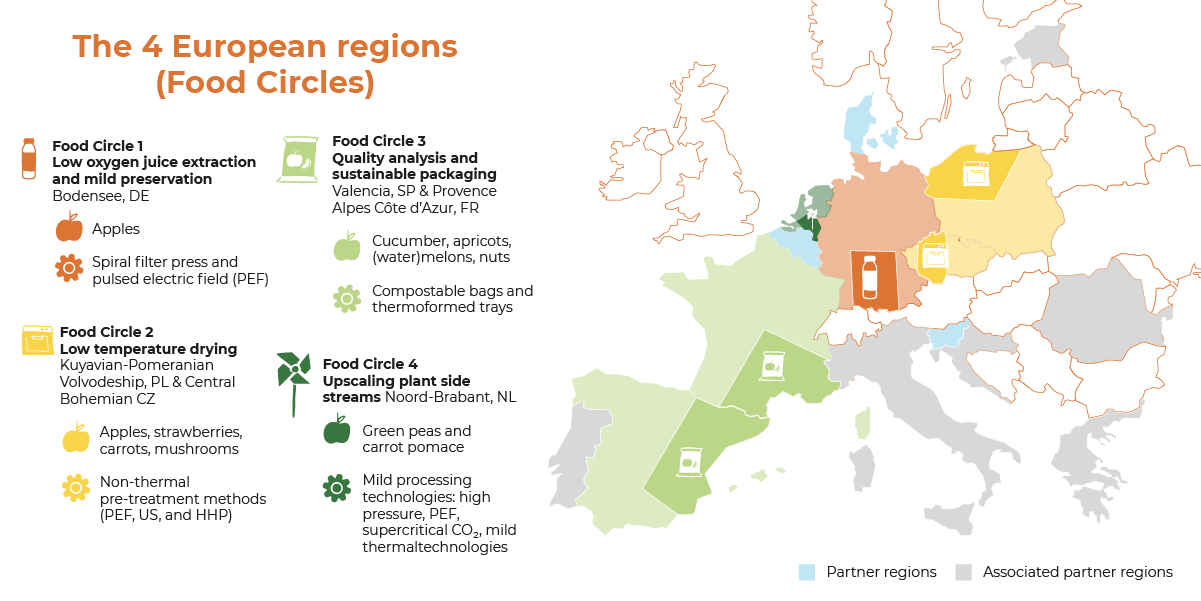

The region

The mild drying units will be tested in the Central Bohemian Region in the Czech Republic and/or Kuyavian-Pomeranian Voivodeship region in Poland.

Project partners

The project partners involved in Food Circle 2 are WULS-SGGW, DIL, VUPP, ELEA, OCHSEN, CEDRUS, AGRO CR and SATU

Food Circle 2 News

Tagus Valley invites FOX for PEF Workshop

On LinkedIn Visit the website tagusvalley.pt [...]

6th Edition FOX Newsletter – Out now!

The FOX team is ready for the final year [...]

FOX Segment Meeting in the Bodensee region, Germany

On Tuesday the 4th and Wednesday the 5th of [...]

NUTRIS publishes in Agro FOOD Industry Hi-Tech Journal

Anita Kušar, from our partner the Nutrition Institute, has published a paper [...]

FOX Animated video: Innovative local fruit and vegetable processing units

Now out: The FOX animated video "Innovative local fruit and [...]

Consumers from Warsaw getting to know the FOXLINK App

On the 30th June, the Faculty of Food Science of [...]

FOX Annual Meeting in Warsaw at SGGW

FOX partners met on the 27th and 28th June [...]

FOX – Food in a Box attending “The Food Club”

Björn Moller from the FOX partner, Fraunhofer, was invited to [...]

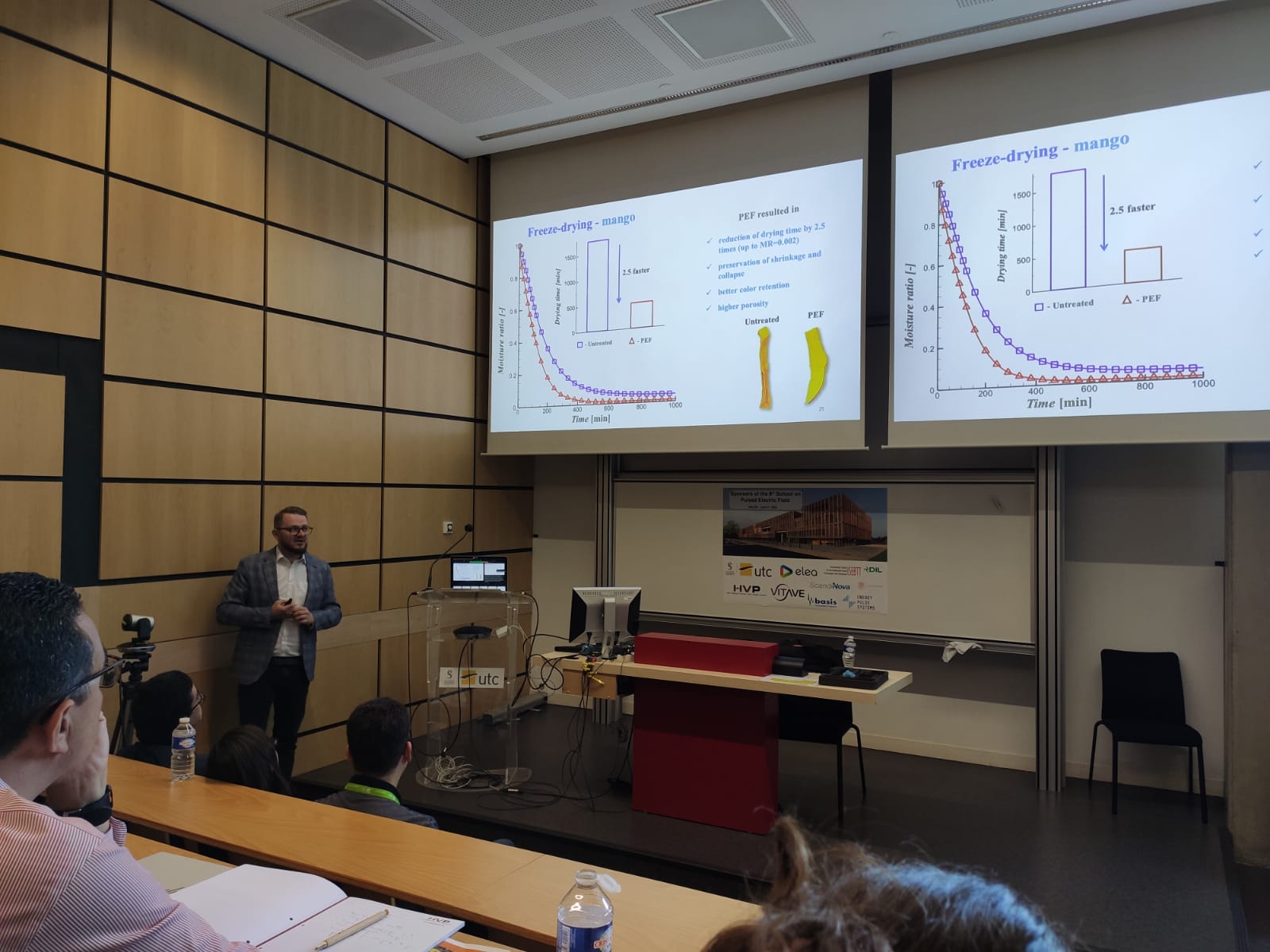

FOX was in PEF School?

Two FOX partners participated in the 8th PEF School that [...]

Infographics: FOX Food Circles Explained

The FOX project works within four areas of innovation, [...]

FOX as an example of Sustainable and Circular Food Production

On the 8th of June, Dr. Artur Wiktor, Assistant Professor [...]

ELEA in AnugaFoodTec 2022

FOX partner, ELEA in the AnugaFoodTec 2022. Anuga FoodTec took [...]

Elea and EnWave Event

Elea and EnWave provided insights and demonstrations of the Synergizing [...]

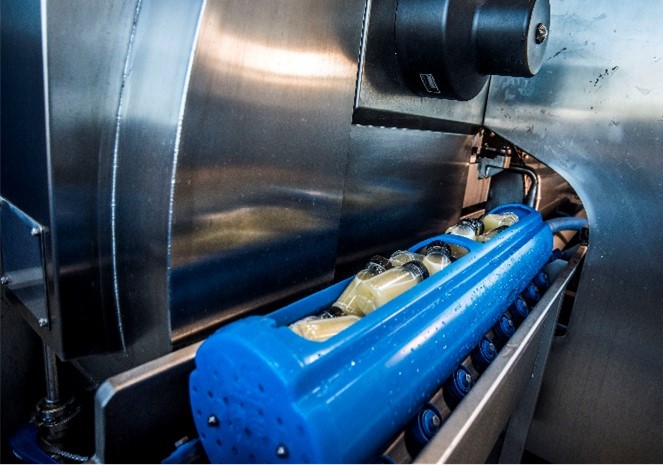

High Pressure Processing (HPP) Technology

FOX (Food in a box) aims to rethink the way we [...]

Drying Technologies

FOX (Food in a box) aims to rethink the way we [...]

PEF (Pulsed Electric Field) Technology

FOX (Food in a box) aims to rethink the [...]

Article about Drying Technologies Food Circle 2

One of FOX's partner in Poland, Warsaw University of [...]

Download the FOXLINK app – Out Now!

Download the FOXLINK app [...]

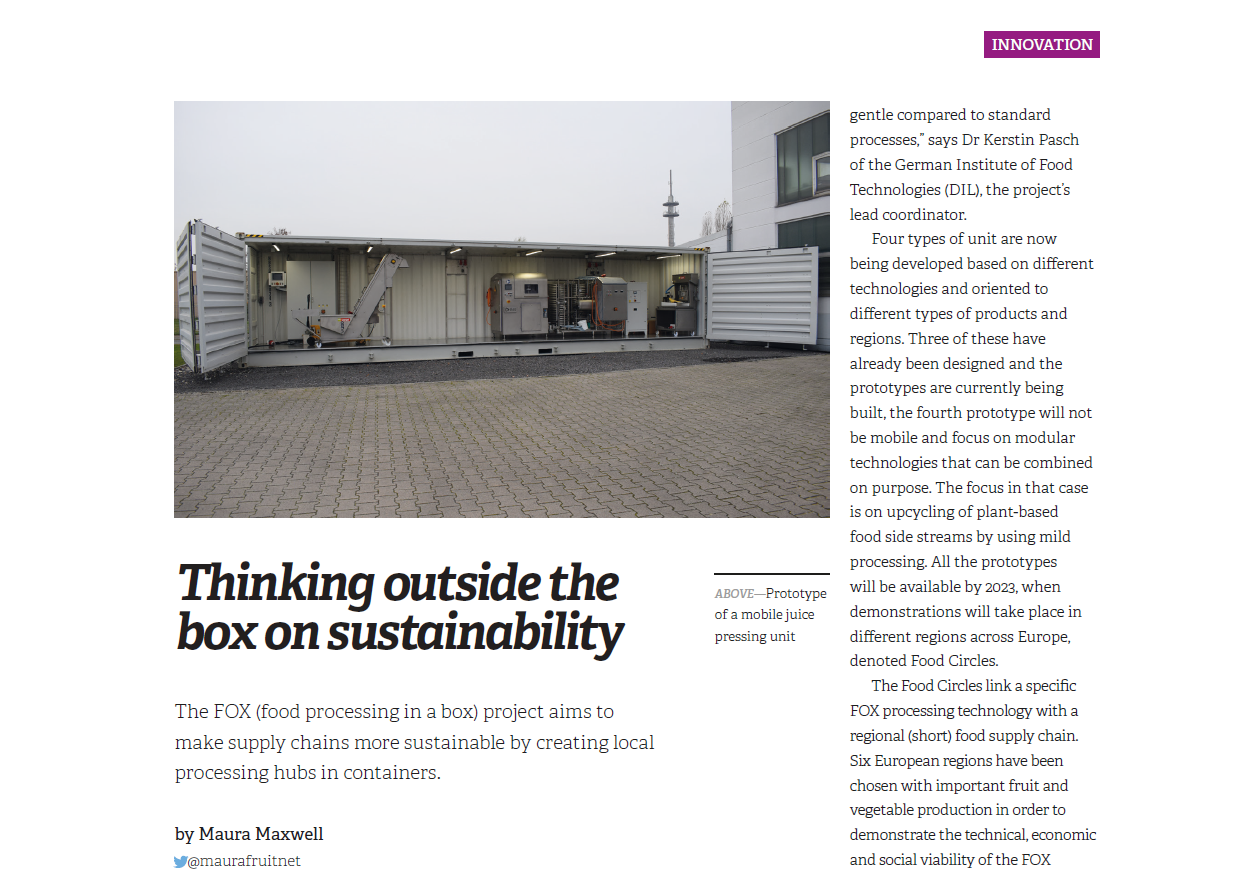

FOX article published in EuroFruit magazine

The latest edition of the Eurofruit magazine showcases [...]

FOX joint segment physical meeting at AINIA

On the 15th and 16th of November, the [...]